Routine non-destructive assay measurements and safeguards inspection of reactor pond fuel assemblies, can be carried out safely and efficiently underwater with ANTECH B2102 Series Fork Detectors.

- Designed for ease of decontamination

- Easily assembled and dismantled for transportation between facilities

- Highly reliable detector electronics

- Can be supplied as a system with all commercially available neutron counting shift registers

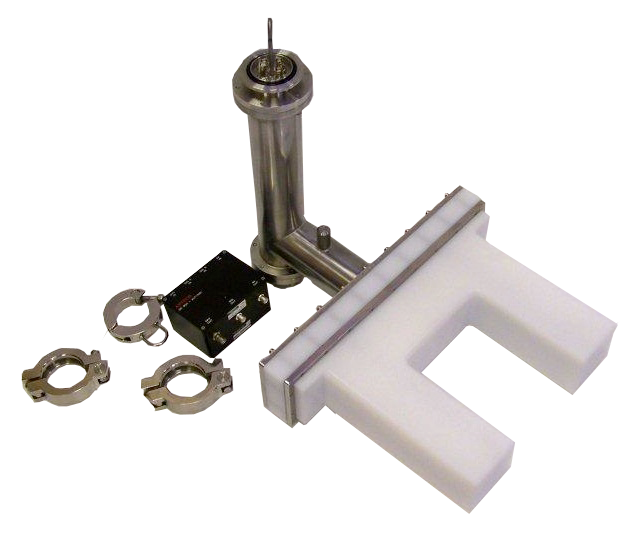

- Detector head and extension pipes supplied in reusable type transportation containers

- IAEA configuration

- BWR, PWR and VVER detector components to a common design, apart from polyethylene detector head, enabling substitution of detector head geometries

Benefits

- High density polyethylene detector head - PWR, BWR or VVER fuel configuration - to be specified by customer

- All external components manufactured from polished stainless steel and polyethylene

- Rugged cable construction with extra strain relief for connectors

- Water-tight detector head and pipe assemblies (IP68)

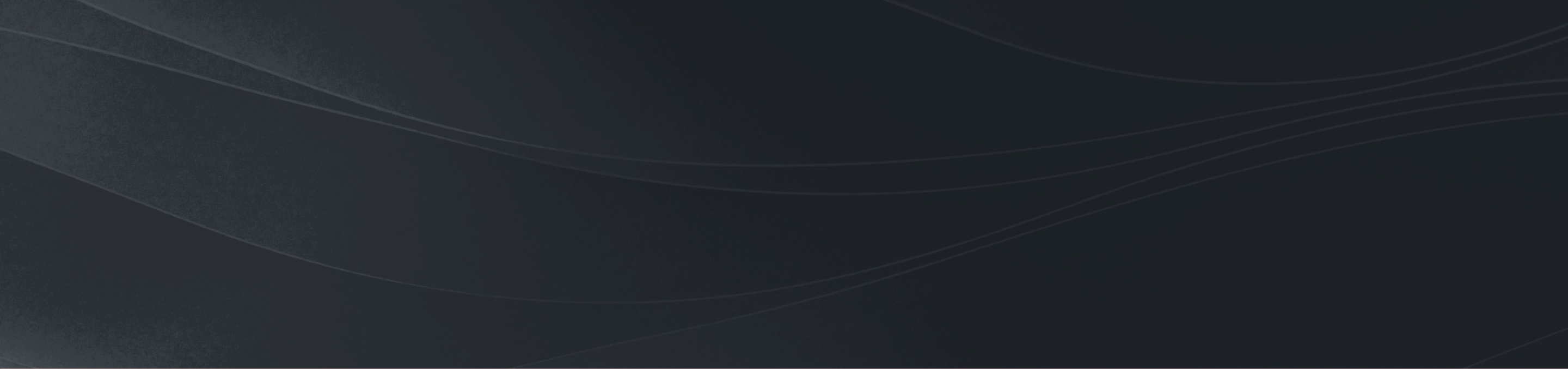

- Supplied with 12000 mm (472.44 in) of extension pipes, connecting flanges, clamps and ‘O’ ring seals

- Mounting bracket for securing to gantry surrounding fuel pond

- Reusable and decontaminable shipping containers for the detector body, other components and pipe sections

- An essential spares and maintenance kit

Features

-

Description

Fork Detectors are used to measure neutron and gamma radiation activity from spent fuel assemblies. They are supplied in three different configurations:

- BWR used to measure Boiling Water Reactor fuel rods

- PWR used to measure Pressurised Water Reactor fuel rods

- VVER used to measure VVER fuel rods (currently used in Russia and the Ukraine)

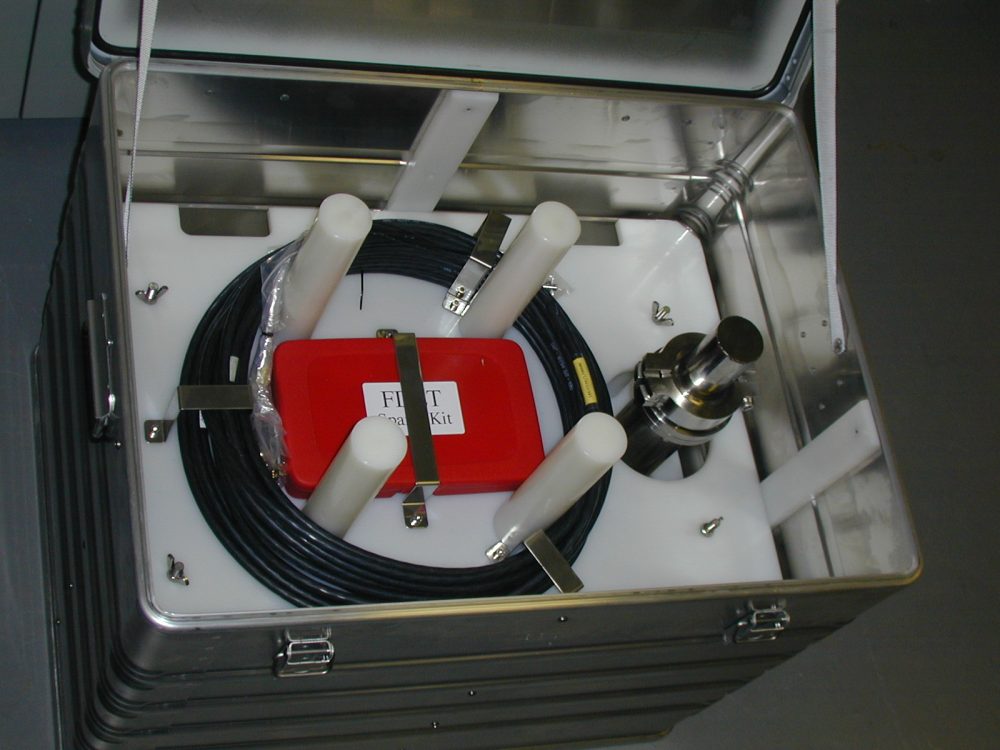

The difference between the different types of unit is the inner distance between the tines of the detector head; the VVER option has the largest detector head and the BWR has the smallest. All other components are identical. The detectors are designed to be portable and easy to assemble to facilitate transportation between sites and quick set-up.

B2102 Series Fork Detectors are manufactured to meet the IAEA’s requirements. Each unit consists of a detector head with integral electronics, a set of connection pipes with associated interconnect clamps, O-ring seals, interconnect cables and a mechanism for attaching the detector assembly to the pond gantry side rails. There are three output signals: two from the neutron detectors which are combined as a single output from the two fission chambers in each tine of the detector head, and one from the two ion chambers which is combined as a single output. These three output signals are fed into the counting electronics, such as a MiniGrand or MicroMesskanal.

Each detector can be supplied tested with nuclear sources (optional) and are delivered with full documentation and test records including a leak test report, Certificate of Conformance and manufacturers test records for preamplifier and detectors.

-

Specifications

Dimensions between tines (W x D)BWR: 165mm x 195mm

PWR: 235mm x 245mm

VVER: 430mm x 425mm BWR: 6.5" x 7.7" PWR: 9.6" x 10" VVER: 17.5" x 17.3"Neutron detectors4 x RS-P6-0805-134 Fission Chambers with 127 mm active length 5"Gamma detector2 x LND Model 52113 Ion Chambers with 127 mm active length 5"PreamplifierPDT 210A (or equivalent)Extension pipes5 x 2000 mm lengths

1 x 1000 mm length,

1 x lifting pipe 78.7" 39.4"