The dismantlement phase of a decommissioning project can generate quantities of rubble which might require characterisation for potential radioactive material contamination. Similarly, site clearance operations can require evaluation of soils. ANTECH offers a number of services for the measurement of soil and rubble in a range of sample sizes and measurement techniques to meet the various requirements.

The ANTECH EMBASSY service measures the contents of excavator buckets. This approach allows the immediate segregation and sentencing of materials and the placement of the measured material into the correct location removing the requirement to handle the material multiple times and hence saving operational costs.

The ANTECH CHARMS service measures the contents of one metre cubed builders bags filled with soil and rubble. This is an effective approach for small-scale operations.

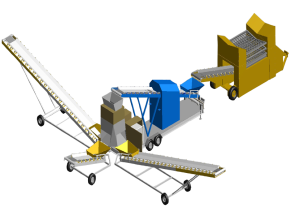

ANTECH also offers conveyor monitoring services for large-scale remediation projects. Measuring soil and rubble on a conveyor allows for rapid and accurate measurements of high volumes of material. ANTECH offers both continuous and tray-based conveyor monitoring as a function of the measurement requirements.

ANTECH Soil and rubble Measurement Services are provided in three distinct phases;

- Phase 1 – Deployment, during which ANTECH works pro-actively with the end user to provide a safe and successful deployment of the ANTECH equipment to the end user site. During this phase, all necessary work instructions, risk assessments and method statements are reviewed and processed to ensure a safe service. Once approved, ANTECH service team members deliver the system(s) to the site, in compliance with site rules and processes.

- Phase 2 – Measurement Campaign, during which the ANTECH service team carry out measurements utilising the system. Throughout this phase, ANTECH subject matter experts (SME) provide technical reviews of the measurements, and the ANTECH quality assurance team ensure the quality and compliance of the measurements with the ANTECH and customer QA processes.

- Phase 3 – Demobilisation and Project close out, during which any outstanding measurement reports are submitted, any questioned results discussed with the end user, and any necessary documentation for the removal of the equipment completed. The equipment is removed from the end user site and the service is concluded.

Measurement Quality Assurance

ANTECH measurement services are all provided with a high level of quality assurance, as it is as critical as the measurement systems themselves. ANTECH’s Integrated Management System (AIMS) has distinct processes and controls for the provision of measurement services. All measurement services are provided in compliance with this QA system.

ANTECH’s measurement services processes for the HRGS assay of bulk “dumpy” bags and 200L drums utilising the CHARMS, IMAGE and UDASS measurement systems have been accredited by UKAS to IEC/ISO 17025. This approach is applied to all ANTECH measurement services, even where not accredited to ensure that the results of the system meet the stringent requirements to assure the end user of the quality of the results.