The ANTECH Model G3652 Tray Assay System is a High-Resolution Gamma Assay System specially developed for Magnox Berkeley Licensed Site for the measurement of fissile material to be stored both in product packages and waste containers such as Yellow Box®, MOSAIK and TRU-Shields.

- Measurement of ILW and FED Waste

- MCNP modelling capability to optimise system performance

- High count rate capability

- Robust design for use in industrial environments

- Operator workstation can be positioned local to or remote from detector and electronics

- Visual image of waste recorded with assay result

- Real-time indication of container fill-levels aiding estimation of when key limits will be reached. Separate fill levels for each container type

- Configurable validity times for background and verification measurements, automated check of performance, automated trending data recorded

- Single software package for measurement of a wide range of container and waste types

Benefits

- High count rate detector with TRP amplifier

- Closed cycle detector cooler for LN2 free operation

- Local or remote operation

- "TrayScan™" complies with stringent Software Quality and Security Requirements

- Flexible software user interface to enable set up for filing multiple container types; Yellow Box®, MOSAIK™, TRU-shield, 3m³ NIREX flasks plus others

- Dose, heat, weight, fissile limit & A2 declaration

- Option to interface to in-cell video cameras and load cell arrays

Features

-

Description

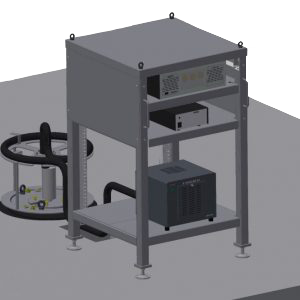

The Tray Assay System consists of an HPGe detector with ultra-high count rate capability (TRP amplifier), closed cycle electro-mechanical cooler and DSPEC 50 high count rate digital signal processor and analyser. The system is designed to view and measure the ⁶⁰co and ¹³⁷Cs content of trays of ILW waste from above, through an aperture in the roof of a highly shielded process area cave. The detector extends down into the aperture and is shielded from the effects of stray radiation by a lead shield designed using MCNP modelling techniques to optimise the performance of the system. The shield is lined with a graded copper and tin liner which absorbs low energy gamma rays generated by the lead due to scattering before they can reach the detector crystal. The detector views the entire tray of waste through a tungsten collimator which has been optimised by MCNP modelling.

The electronics are mounted in a thermostatically controlled heated enclosure next to the detector. The system computer, monitor and printer can be either mounted local to remote from the electronics. The system interfaces with the waste tray weigh scale and in-cell video camera.

Software Overview

Key to performance and flexibility of the system is the software which consists of two dedicated packages which run on a Microsoft Windows 7 Pro® (64-bit) operating platform.

- ANTECH TrayScan™

- ORTEC GammaVision®

TrayScan has been developed by ANTECH to meet specific requirements for the measurement of ILW and FED, in accordance with Magnox Measurement Quality Requirements.

As well as measuring the ¹³⁷Cs and ⁶⁰Co activity on a tray of waste, the system keeps a running total as waste is added to a container. TrayScan software provides the functions and algorithms to enter information, (both manually and automatically) and facilitates the data acquisition and analysis required for assay. It also reports information both on-screen and in hard copy format, of results for a wide range of storage containers. The TrayScan software also:

- Records radionuclide activities in order to produce cumulative and final package inventories

- Provides a visual message to the operator to indicate the detection of a potential fuel piece (above a certain mass) in the waste. It estimates the activity and allows the facility to ‘accept/reject a measurement’ and add the tray to the container based upon the outcome.

- Records cumulative and final package content for a range of parameters and visually indicates when the package limit is being approached as it is filled.

- Provides a means to automatically read the mass of tray waste being assayed.

- Provides the capability to deal with different waste streams.

- Supports regular functionality (control) testing of the equipment through quality control measurements in order to confirm correct operation prior to the assay of waste items.

AMETEK/ORTEC GammaVision™ 8.0 Spectrum Analyser and MCA Emulator is supplied to analyse the spectra and extract the counts in peak for the gamma lines analysed.

-

Specifications

Detector Shield Assembly (H x Φ)838 mm x 500 m (at widest point)Instrument Enclosure (H x W x D)720 x 720 125 mmWeight Detector/Shield Assembly150 kgElectrical connections220 - 240 Vac

(110 Vac operation via step-up transformer)

Frequency: 50/60hz, 1200W (max)HPGE Detector SystemORTEC GEM-F7040P4-PL with TRP amplifier and X cooler III