The ANTECH model G3010 Automated Gamma Spectroscopy System (AGSS) or ‘Sample Changer’ is an effective solution for performing automated, unattended, high-resolution gamma spectroscopy (HRGS) measurements and analysis of bulk samples in a variety of sizes and types of Marinelli beakers. The Sample Changer features an automated pick-and-place system to move Marinelli beakers too and from a highly shielded lead measurement chamber, and a high efficiency HPGe detector completing the measurement. With customisable configurations, and quick-change sample trays, the AGSS provides a versatile solution to achieve laboratory sampling measurements with accurate results.

- Easy set-up and use with a swappable beaker plate for rapid change of different sample sizes

- Full automation allows unattended batch operation

- Integrated safety system, including magnetic switches in upper level access doors, operator control panel status lights and safe-torque off motor feature.

- Flexible design for a wide variety of sample sizes and configurations.

- Software diagnostics and user help

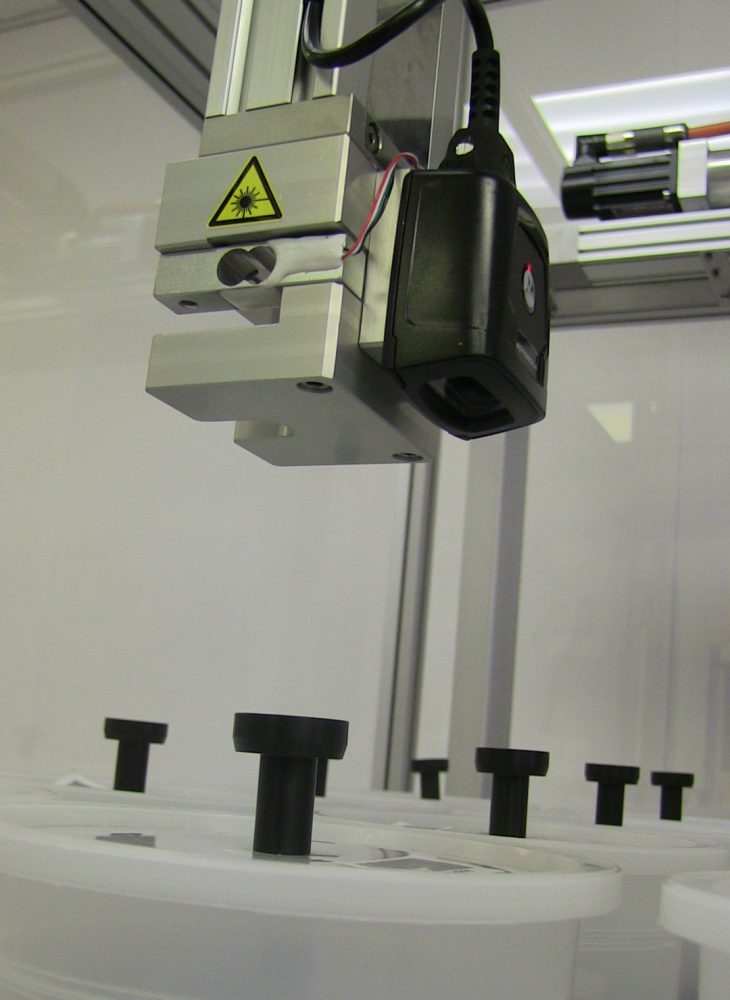

- Optional integrated weigh scale and barcode reader for automated batch identification.

Benefits

- 30% Efficient High Purity Germanium (HPGe) detector as standard available with both electro-mechanical and LN2 coolers.

- Enhanced automation options based on Allen-Bradley® PLC motion technology.

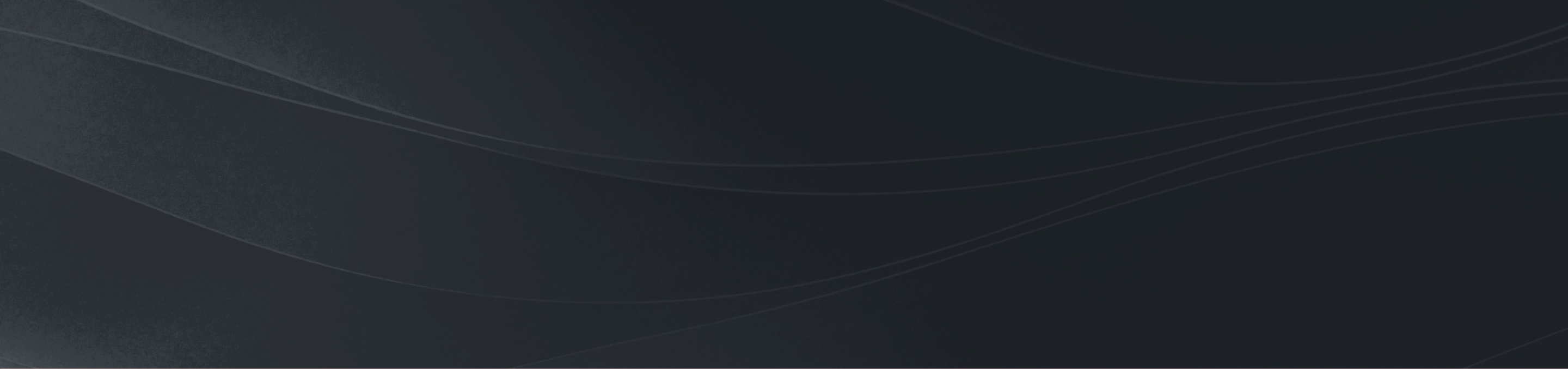

- 100mm thick virgin lead shield, graded with tin and copper to ensure low background counts.

- Intuitive user interface for integrated and unified scheduling and analysis software

- Operator control panel for manual control.

- CE compliant with many in-built safety features.

Features

-

Description

The Sample Changer consists of an extruded aluminium frame encompassing the Sample Loading Position, Pick-and-Place System, Measurement Chamber and System Electronics. The frame provides both mounting positions for the hardware, but also protection for the operators. Transparent panels in the frame doors allow for full visibility during operation, and an integrated magnetic interlock safety circuit ensures that the system cannot be operated without the doors being shut.

The Sample Loading Position consists of a mounting position for the Sample Tray into which the Marinelli Beakers are loaded. The Sample Tray consists of a grid of sample positions in a UHMWPE material, with identifying numbers for each position. Locating pins allow for a quick swap of the Sample Tray which enables a range of beaker sizes and configurations to be measured on the machine. GammaSample+ incorporates a Sample Tray configuration screen, allowing for multiple tray types to be stored as configurations for simple use when setting up a batch measurement.

-

Specifications

Sample Size0.25L, 0.5L, 1L, 2L and 2L Marinelli Beaker.Tray sizeTypical Tray Sizes:

30x 0.25L

25-30x 0.5L

20x 1L, 2L

12x 4LDetection Efficiency30% Typical, with options of higher and lower available.Shielding100mm Virgin Lead lined with Tin and Copper. 4"Analysis SoftwareANTECH GammaSample+ with Ortec GammaVision analysis software