The ANTECH Universal Surface Dose Drum Monitor reproducibly measures the surface dose rate of large numbers of steel drums containing radioactive waste. The product is designed:

-

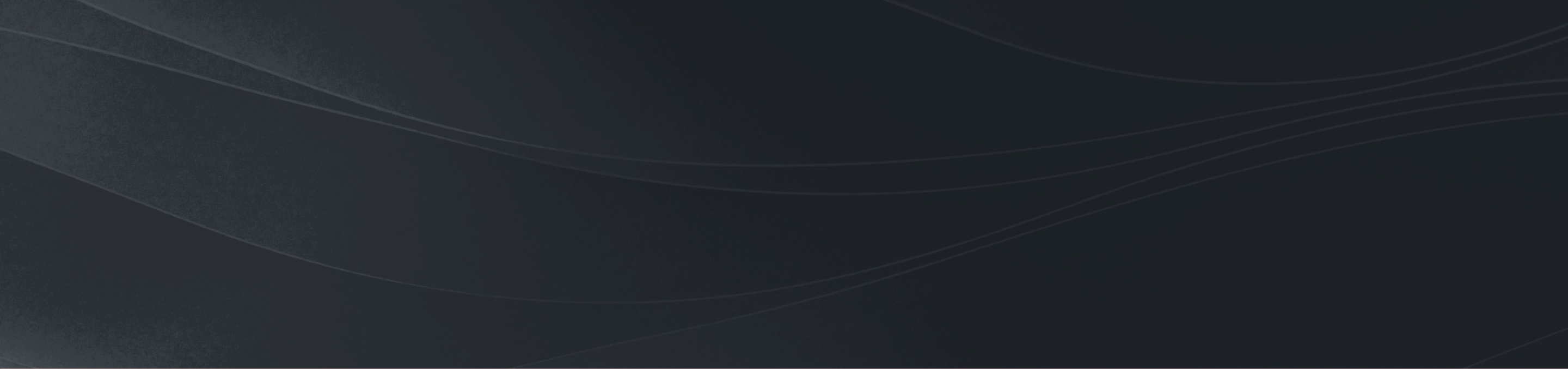

- For standalone operation with a drum rotation platform for loading and unloading by a forklift,

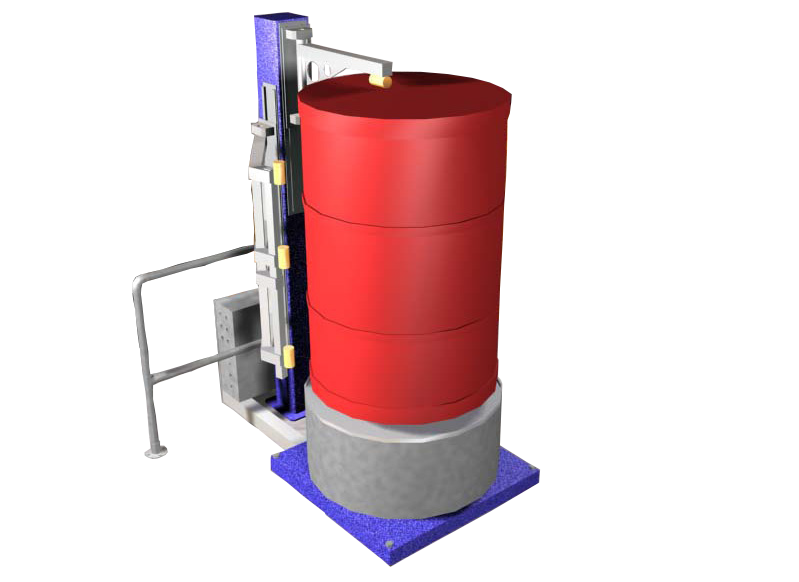

- For standalone operation with short entry and exit roller conveyors

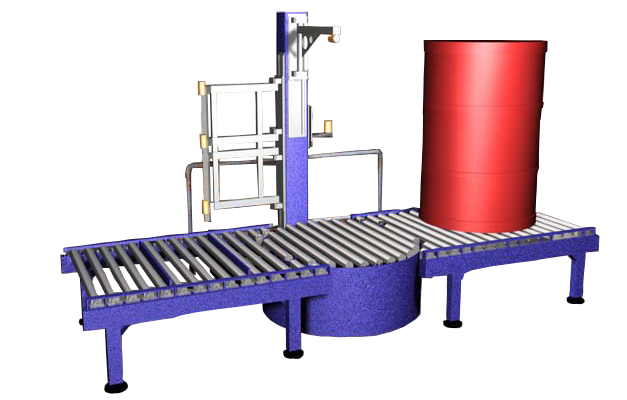

- As a surface dose rate monitoring station with a conveyor drum rotation platform for integration into a conveyor mechanical handling system such as a waste drum measurement suite

- For integration into ANTECH’s range of gamma drum monitors including open detector, segmented gamma scanner (SGS), Wide-range SGS (WR-SGS) and tomographic gamma scanner (TGS) products.

- Automatic, reliable and consistent measurement of the surface dose rate of drums

- Meets measurement requirements of US DOE transport regulations

- Secure measurement records, all data fully archived

- Reduced exposure to operators

- Low maintenance and robust construction

- Complies with European Safety Norms

- Designed for easy wipe down and cleaning

- Easy integration with high through-put batch measurement plant

Benefits

- Fully adjustable for a wide range of drum sizes

- Shielded and collimated energy compensated Geiger Muller detectors

- Tungsten detector shielding

- Dedicated dose rate measurement microprocessor

- Integral electronic weighing scale

- Operator control station, local or remote modes of operation

- Suitable for forklift loading and unloading

- Provision for background measurement and subtraction

- CE and UKCA marked

Features

-

Description

The ANTECH G3030 Universal Surface Dose Drum Monitor reproducibly measures the surface dose rate of large numbers of steel drums containing radioactive waste. Five shielded Geiger-Müller detectors are used to measure the dose rate of the top, bottom and sides of the drum under test. The lower detector has a fixed position and the three side detectors and one top surface detector are adjustable to accommodate different drum sizes. A sixth detector is positioned at one metre away and ‘views’ the entire drum surface. During the measurement a servo drive senses the position of the drum surface and maintains the three side detectors at a constant distance regardless of the drum ovality or its position on the turntable.

An operator console allows fully automatic operation of the measurement sequence, real time display of measurement parameters, entry of drum type and identity, report generation, data validation and archiving. The operator console software allows ‘stand-alone’ operation in manual mode for single drum evaluation and supports a test mode for initial commissioning and preventative maintenance. A series of 6 dose rate graphs (obtained as the drum is rotated) are included in the measurement report for each drum.

-

Specifications

Drum Size440mm to 1130mm diameter

880mm to 1700mm height 17.32" to 44.49" diameter 34.65" to 66.93" heightCapacity1000 kg 2200 lbWeigh Station Accuracy±2% of full scaleSurface Dose Range3 μSv/h to 10 mSv/hDetector Channels7 (expandable to 16)