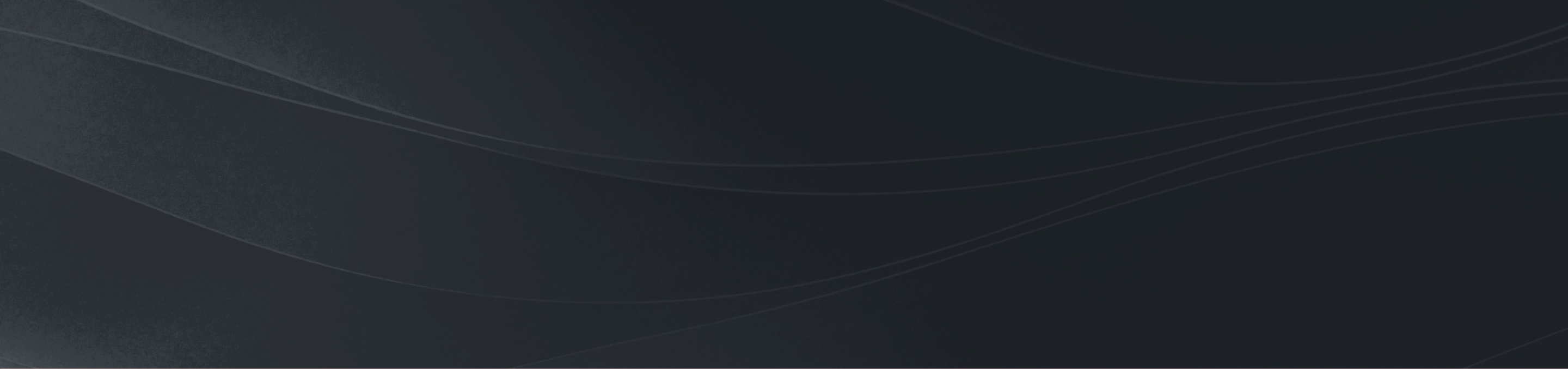

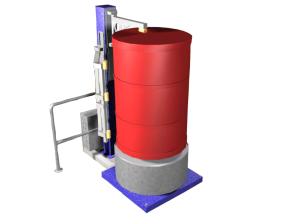

The ANTECH G3200 Series of Segmented Gamma Scanners (SGS) are high accuracy HRGS systems for the assay of waste contained within 220L (55 US Gallon) and 320L (85 US Gallon) drums.

- Discrete or Helical Scanning options.

- Configurable modular design for optimisation for end user requirements.

- Can be easily upgraded to Wide-Range Segmented Gama Scanner (WR-SGS) or full Tomographic Gamma Scanner (TGS)

Benefits

- 40% Standard HPGe Detector

- Options for Electro-mechanical or LN2 cryogenics

- 50mm Fixed Aperture Collimator

- Optional Tungsten Filters for High Activity Drum

- Integrated Precision Weigh Scale

- Automatic or manual operation

- User selectable one pass or two pass measurement mode operation

- Multiple drum handling solutions available- manual or automatic conveyor loading/unloading

- Optional built-in Geiger-Muller dose sensor and waste drum bar code reader

Features

-

Description

The ANTECH Model G3200-340 Segmented Gamma-ray Scanner (SGS) is designed to provide a non-destructive method for measuring the radionuclide content of typically low-level and intermediate level waste (LLW and ILW) including corrections for attenuation. Segmented gamma ray scanning is applicable to waste of a variety of matrices and chemical forms. It is particularly relevant when the chemical form and the relationship between the nuclide and matrix are unknown.

The drum or sample is rotated about its vertical axis as horizontal segments are scanned in order to allow for any inconsistencies in the matrix density and to average inhomogeneity. A vertical profile of the gamma ray transmission and the nuclide concentration for the drum or sample is recorded. The spectrum for each vertical segment or the summed drum or sample spectrum can be viewed in real time on the software interface. Corrections are made for to each spectrum for count defendant losses from pulse pile-up and analyser dead time.

For each horizontal segment of the drum or sample, the average linear attenuation coefficient is calculated by measuring the transmitted intensity of the external transmission source. This is known as the transmission measurement. The transmission source is mounted on an arm directly opposite the detector. A shutter opens for the transmission scan and closes during the emission scan to shield the transmission source. In this manner the attenuation or density correction is determined on a segment-by-segment basis for the entire drum.

In a similar manner an emission scan or measurement is performed in which an emission spectrum is obtained for each vertical segment of the drum. Each segment emission spectrum is corrected for gamma ray attenuation using the transmission data described above and the radionuclide content of each segment is determined from the gamma ray spectrum peak areas associated with appropriate regions of interest in the spectrum corresponding to the desired radionuclides.

The result for the entire drum is the sum of the results for all of the scans, corrected for any scan overlap. When the transmission and emission scans are performed separately, the process is called a two pass scan. This is the case when the transmission source may interfere with the emission measurement. When a single scan is performed and both transmission and emission data is obtained the process is referred to as a one pass measurement.

The ANTECH implementation of the SGS technique complies with Standard Test Method for Non-destructive Assay by Segmented Passive Gamma-ray Scanning, ASTM standard number C1133.

-

Specifications

Drum Size220 litre, 340 litre standard, customisable for non-standard drums. 55 US Gallon, 85 US Gallon standard, customisable for non-standard drumsAnalysis SoftwareANTECH GammaScan+, SGSAssay Analysis and Ortec GammaVisionDetector40% High Purity Germanium (standard), Optional higher and lower efficiencies availableDigital MCAOrtec DSPEC-50 or DSPEC-50AShielding50mm Lead Shielding around the Detector diameter, and Lead Back Shields on the rear. All Lead is housed within protective casing for operator safety. 2" Lead shielding