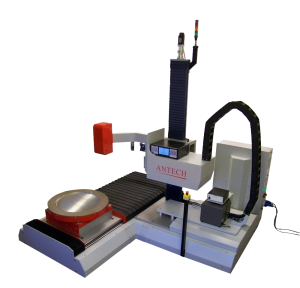

The ANTECH G3600 Series of instruments are a range of non-destructive assay machines which operate in line with the ISO 19017 Open Detector methodology for the high resolution assay of waste drums in both 200L (55 US Gallon) and 340L (85 US Gallon) drums. This methodology is optimised for the assay of relatively homogenous drums, both in matrix composition and activity distribution, resulting in a highly efficient drum assay. Drawing the from the ANTECH modular Universal Drum Gamma Design set, the G3600 series of instruments can be easily customised and configured for a range of different installations and applications, and for both low and high activity.

- High efficiency drum assay of homogenous waste drums.

- Measures wide range of sample activity from very low-level waste (VLLW) to high activity remote handled (RH) waste.

- Configurable and customisable design set to meet any requirement.

- Quality Assurance measurements and background subtraction for accurate measurement.

Benefits

- 40% efficient HPGe detector with options of both electro-mechanical and liquid nitrogen cryogenics.

- 2" detector lead shield lined with tin and copper.

- Optional horizontal axis of motion and tungsten filter sets for high activity drum measurements.

- Integrated weigh scale network.

Features

-

Description

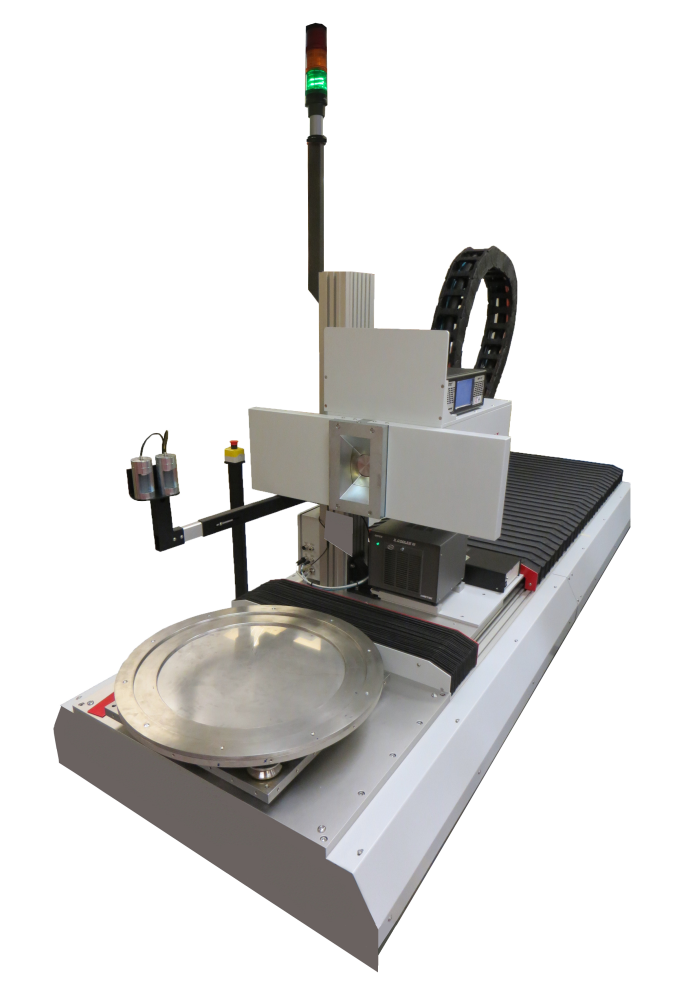

Far Field Gamma Monitor Systems

The G3600 series of systems encompass a range of machines for the non-destructive assay of waste drums using the Far Field or Open Detector methodology. The core of all G3600 systems are based around two main sub-assemblies; a Detector Column and a Rotary Platform.

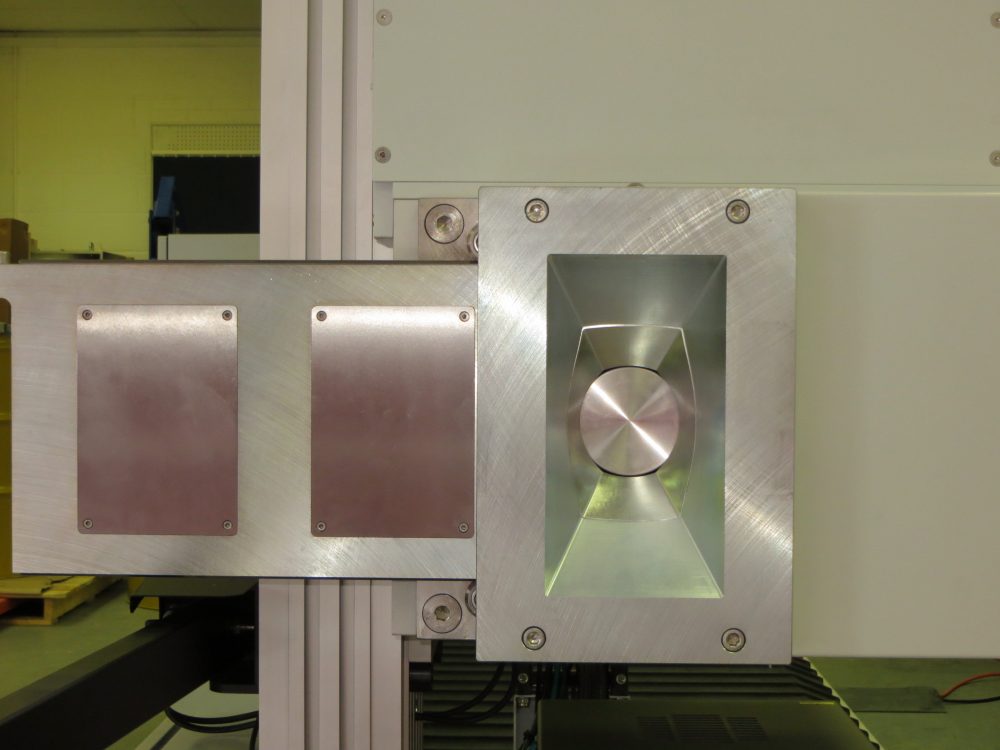

The Detector Column provides a mounting position for the High Purity Germanium (HPGe) detector and its shielding, at the optimum height for the drum when mounted on the rotary platform. For standard applications of 200L (55 US Gallon) and 340L (85 US Gallon), the detector pillar is fixed in a single vertical position. In applications where a range of container types, including non-standard containers, are to be measured, a vertical axis of motion with configurable height positions for different container sizes can be incorporated to ensure the optimum measurement position for all container types. The HPGe detector is mounted in a cylindrical lead shield, at least 50mm (2″) thick, including lead back shields to provide high background shielding for the detector. This ensures only contributions from the drum being measured are analysed, with background subtraction being incorporated in the analysis software.

The detector field of view is optimised using an MCNP designed, fixed steel collimator with a conical-trapezoidal profile to both reduce the effects of background radiation and optimised the field of view of the drum. Through this, the entire sample container is in the field of view of the detector at all times. In front of the collimator, optional filter sets can be automatically deployed, with a range of thicknesses selected to suit the measurement range. When deployed, the tungsten filters cover the detector crystal, to reduce the counts and detector dead time of the system. This, in combination with the optional horizontal motion, allows the G3600 range to be used to measure high activity drums.

The Rotary Platform provides a measuring position for the drum, which is rotated about its axis during to scan to minimise the effect of any radial inhomogeneity. The assembly consists of a Turntable, with centralising rings to allow for easy loading of the drum, mounted on top of a low friction bearing and driveshaft, driven by a low backlash, multi-turn encoded servo motor controlled by the system electronics. 0-degree position sensors, combined with the motor encoding ensure consistent radial start positions for rotation counting. The assembly is mounted on a network of high-precision load cells to provide gross and net mass values for the container, used for density correction of the scan.

-

Specifications

Drum Size220L and 340L standard, with special sizes available. 55 Gallon and 85 Gallon standard, with special sizes available.Load Cell Capacity500kg minimum, with options for higher capacities if required.Germanium Coax Detector Efficiency40% standard, with options for higher or lower efficiencies available.Shielding50mm thick radial graded lead shield.

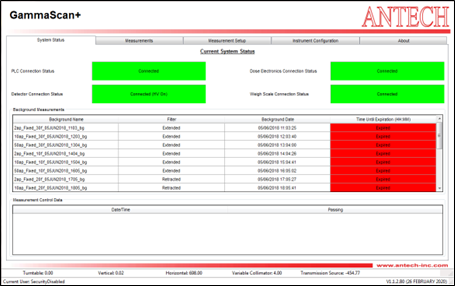

Options for increased shielding thickness available. 2" thick radial graded lead shield.Analysis SoftwareANTECH GammaScan+

ANTECH IsoCorr